|

You Are Visitor Number

Main Navigation

Home Page

Company History

Contact Information

Offered Services

Products & Solutions

Parts & Accessories

Air & Oil Filters

Air Compressors Brands

Air Compressors Type

Used Air Compressors Systems

Compressor Rental Middle East

Air Compressors Rentals Jordan

Latest News

Featured Services

Preventive Maintenance

Machine Installation

Machine Servicing

Machine Inspection

Machine Air Audit

Airend Overhauling

Airend Repair

General Information

Air Compressors Info

Compressed Air Purification

Air Compressors Advantages & Disadvantages

Purchasing Guideline

Care & Maintenance

Air Compressors Brands

Ingersoll Rand

Atlas Copco

ALMiG

Broomwade

Compair

Demag

Elmo Rietschle

Hydrovane

Kaeser

Sullair

Air Compressors Types

Belt Driven

Centrifugal

Dental | Medical

Diesel

Direct Drive

Electric

Industrial

Low Pressure

Medium Pressure

High Pressure

Oil Less | Oil Free

Portable

Reciprocating

Rotary Screw

Single | 2 Stage

Vertical | Horizontal

Parts & Accessories

Air Filters

Oil Filters

Separator Elements

Service Kits

Inline Elements

Lubricants | Oil

Airends | Air Ends

Air Line Filters

Drive Belts

Gas Turbine Air Intake

Inlet Valves

Intercoolers

Oil Stop Valve Kits

Pressure Sensors

Pressure Switch

Seal Kits

Solenoid Valves

Drain Solenoid Valves

Tanks

Temperature Sensors

Thermostatic Valves

Vacuum Pump Spares

Valve Kits

Middle East Compressors

Filters in the Middle East

Compressor Parts Middle East

Jordan Air Compressors

Filters In Jordan

Compressor Parts In Jordan

|

Saturday, April 26, 2025 5:37 AM

Service Kits

Developed and Built Specifically to fit the OEM bills of material

NPS offer an extensive range of service kit options for Atlas Copco, Ingersoll-Rand, Sullair, Wilkerson, Gardner Denver, Kaeser, Compair, Holman, Broomwade, Demag, Elmo Reischle, Hanshin and Hydrovane Brands of Air Compressors. All NPS service kits are direct replacements to the OEM kits and meet the ISO 9001 standards and requirements.

NPS can provide Separator kits, Preventative maintenance kits, Filter kits, Air and Oil filter kits, Check valve kits and Thermostatic valve kits including VSD ranges, in fact everything needed to fully service a compressor unit. Service Kits from NPS are available to fit your time interval service schedules.

Air Filters, Oil Filters and Separators

Designs that meet the OEM required performance and specification

NPS Air and Oil filters and Separators are manufactured with the highest quality filtration and separation media. The filtration and separation media used ensures that NPS separators can be used with all and any types of oils (mineral, semi synthetic or fully synthetic)

In-Line Elements

Compatible with most manufacturers

NPS offer replacement filter elements for a number of manufacturers, including Atlas Copco, Ingersoll-Rand, Sullair, Wilkerson, Gardner Denver, Kaeser, Compair, Holman, Broomwade, Demag, Elmo Reischle, Hanshin and Hydrovane.

Our extensive range offers inline filter elements that can be used in a variety of industries. NPS filter elements include pre-filtering, general purpose, oil removal and activated carbon.

Lubricants

For Optimum Compressor Performance

From Mineral, Semi synthetic to Fully synthetic, Rotary screw, Rotary vane or Reciprocating, NPS have a lubricant that will meet your requirements and type of Air Compressor.

NPS offers a wide variety of lubricants and coolants for rotary screw, rotary vane, reciprocating, centrifugal or piston compressors that offer an excellent alternative to OEM lubricants. NPS can offer alternatives from our standard lubricant range and provides a veriety of alternatives for non standard lubricants.

Used Compressors

Used Compressors that have been tested & serviced are available

NPS has a variety of Used Compressors that are available. These compressors have been serviced and tested to ensure that they are in a good operating conditions.

To View A List of Used Compressors Available for Sale Please Click Here

Used Dryers

Used Dryers that have been tested & serviced are also available

NPS has a variety of Used Dryers that are available. These dryers have been serviced and tested to ensure that they are in a good operating conditions..

To View A List of Used Dryers Available for Sale Please Click Here

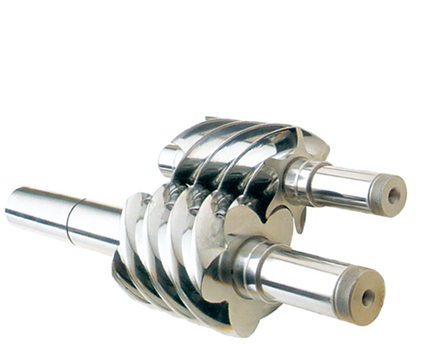

Airend Overhauling Facility

Guaranteed Airend Rebuilding

National Plant Sales specializes in rebuilding rotary screw airends for all air compressor brands. With such a high number of remanufactured airends in the field, NPS offers a reliable and reasonably priced alternative to factory exchange airends.

All of our rebuilds include new bearings, gaskets, seals, orings, rotor repair, oil pump rebuild, inlet valve rebuild and end plate repair as needed for your convenience. On direct drive units we also service the drive motor, clean & bake the windings and install new bearings and seals to ensure optimum performance.

All Airend Rebuilds come with our exclusive 1 or 2 year warranty.

Airend rebuild features:

Remanufactured to OEM Specs

Quick Turnaround Time

Sealing Strip Repair or Replacement

Keyway Repair

Rotor Shaft Repair

End Plate Repair

Dynamic Rotor Balancing

Drive Gear Sets in Stock

Teflon Rotor Coating

ASME Welders

What Is The Process The Airend Goes Through In A Rebuild?

- Your airend is loaded off and taken immediately to the disassembly area which contains mounting stand, overhead crane and oil pit for collecting oil. A document is generated for disassembly, teardown and spec sheets. This document follows the airend through the entire rebuilding process to ensure accurate documentation.

- Once the airend is disassembled, damage and measurements are recorded, and pictures are taken identifying the primary problem areas.

- At this point a quote is written for the rebuild and submitted to the customer for approval.

- The disassembled airend is then placed in one of the self-contained cleaning systems to be cleaned.

- Once we receive the OK and Purchase Order number from the customer, all parts that require work are brought to different areas of the shop and the repairs begin. The front and rear covers will be metalized using the thermal ARC system, when finished depending on the size of the cover, its moved to either the 20" or 36" Blanchard grinder for finishing.

- The front male rotor bearing journal is mounted and turned on a lathe and will also be metalized and ground according to specs.

- The main bore area if damaged will be plated and bored on a vertical boring mill.

- Seal strips are built up and re-cut on a custom jig.

- Depending on the extent of the damage, the above work normally takes one to two days to complete.

- All components are then rewashed and taken to the assembly area, where all the bearings, seals, gaskets, and related materials needed to complete the assembly are pulled from inventory.

- Before assembly takes place all the bearing pockets, bores, and alignments are rechecked. The two rotors are then checked for proper balance and alignment.

- The bearings are removed from the boxes and re-measured for proper fit before installing.

- To insure that the manufacturer's specs are being met, the unit is continually measured and re-checked for accuracy

- Upon completion all open ports are plugged with plastic caps and the inlet taped. The airend is now ready to be skid mounted and painted.

- As units enter the shipping area all necessary shipping documents and start-up procedures are attached to the unit, and trucking details are arranged.

- This whole process will normally take on the average 3 to 5 working days, depending on the size and degree of damage. We have setup our shop so the work flows through on a orderly path to insure that all our inspection steps and quality controls are adhered too.

We carry the following Air Compressors Parts and Accessories for your convenience...

We Supply Air Compressors Parts & Accessories for the following Brands

|